Basic Info.

Model NO.

FCM004

Alkali Content

Alkali Free

Transport Package

Custonized

Specification

440gsm

Trademark

kaiao

Origin

China

HS Code

5401201000

Production Capacity

50000/Week

Product Description

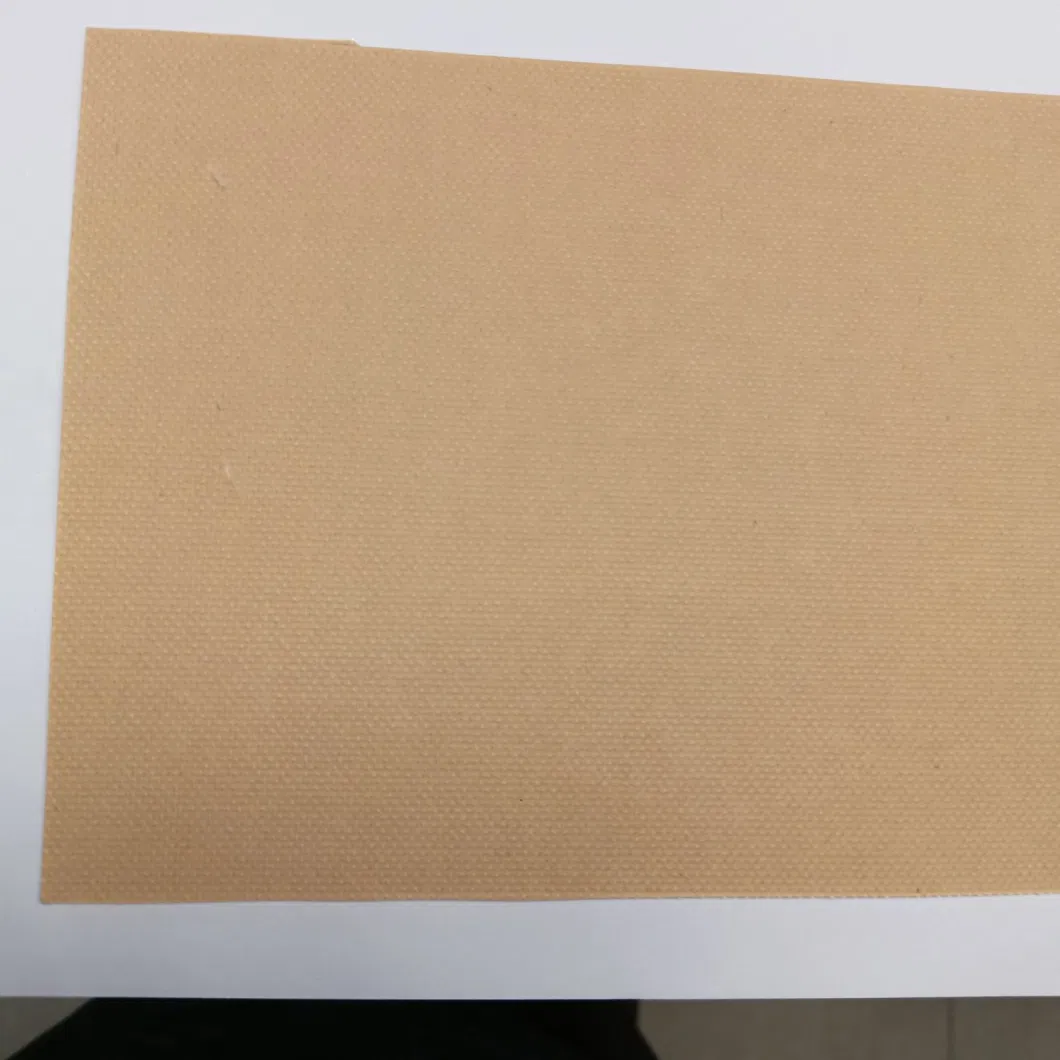

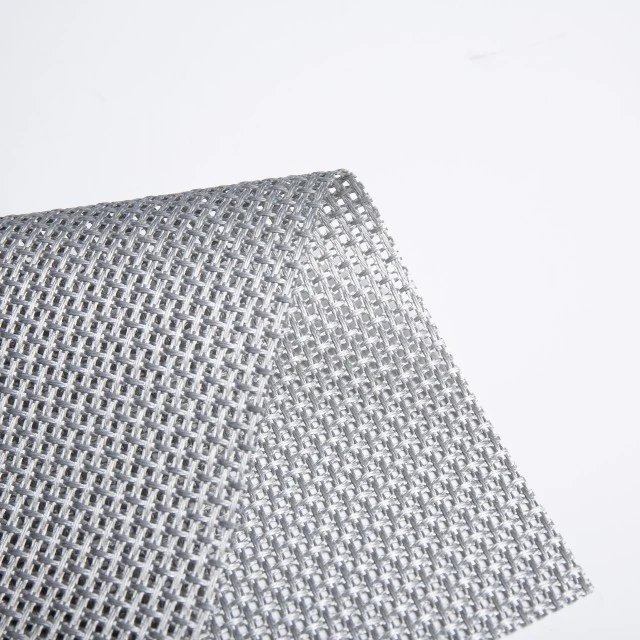

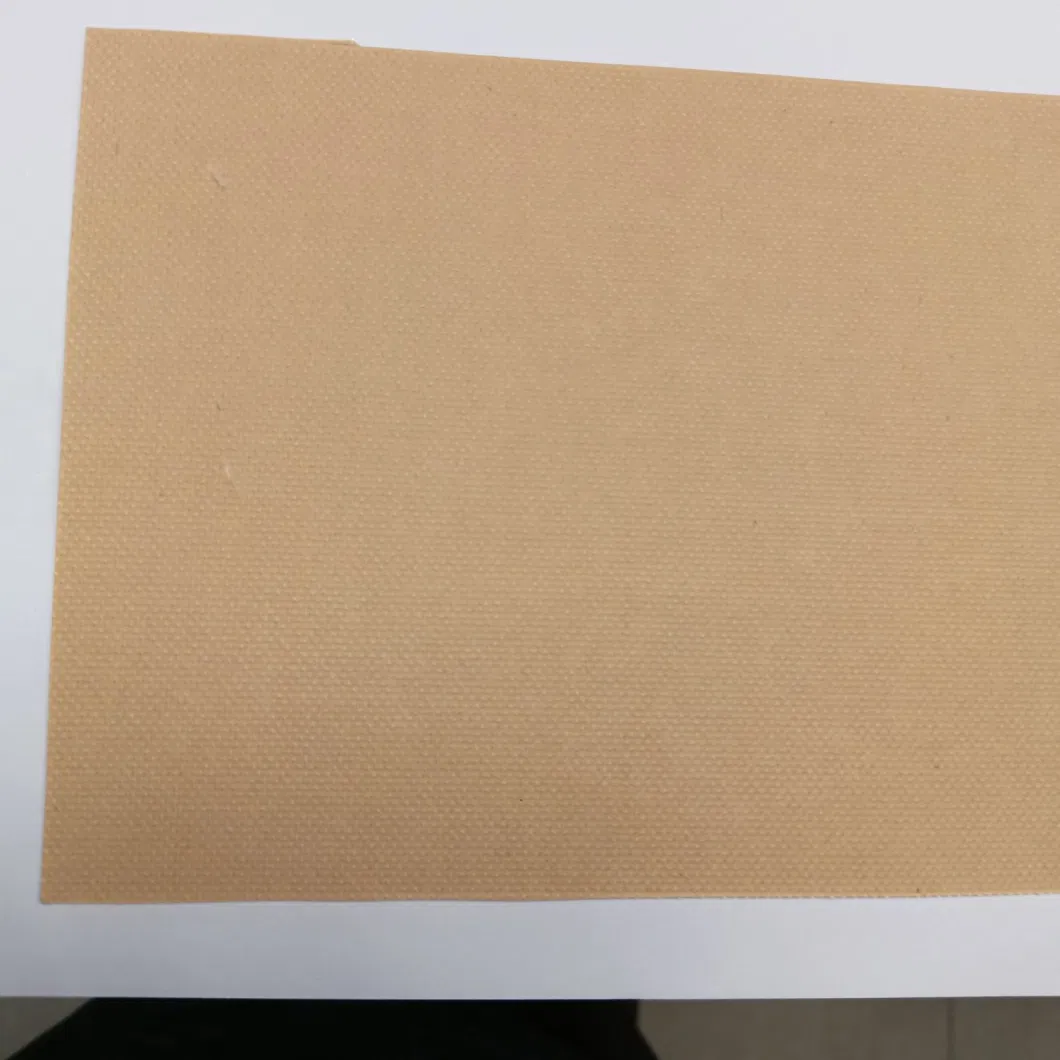

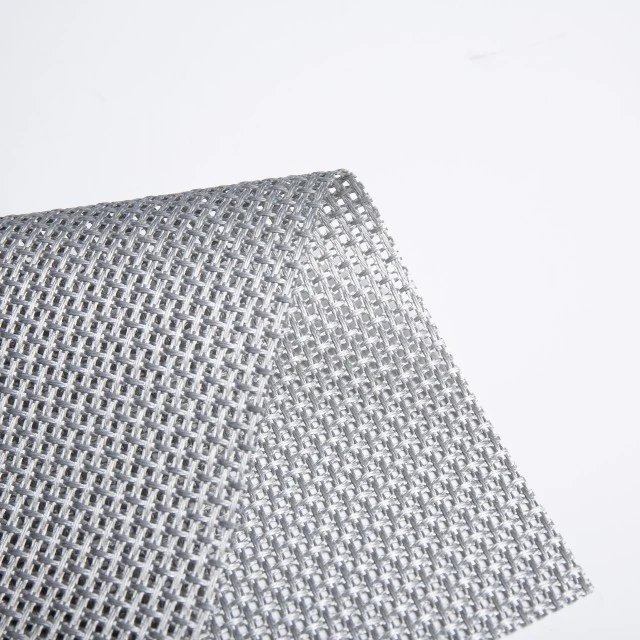

PTFE Coated Fiberglass Open Mesh Belt

Mesh belt is one kind of high performance and multipurpose composite

material.which is high-quality glassfiber coated with PTFE emulsion.

Characteristics:

(1).Working temperature resistance from -70ºC to +260ºC.

(2).Non-stick surface,easy to clean.

(7).Fire Proof.

(8).Air permeability of the conveyor belt can reduce the heat-consuming,

and improve the drying efficiency.

Applications:

Used in any industry which need conveyor belts in heat air flow or heat

processing.

(1).Textile and dyeing: drying for textile printing, dyeing, shrinking,

on-woven fabric, and in industry oven.

(2).The loose-dryer, offset, UV curing machine, paper oil drying, UV

drying, plastic printing drying.

(3).High-frequency wave drying, microwave drying, food refrigeration and defrost, baking, packaging heat shrinking.

Mesh belt is one kind of high performance and multipurpose composite

material.which is high-quality glassfiber coated with PTFE emulsion.

Characteristics:

(1).Working temperature resistance from -70ºC to +260ºC.

(2).Non-stick surface,easy to clean.

(3).Chemical resistance.

(4).Cood stability in size,high strength,good mechanical performance.

(5).Bending fatigue resistance,and can be used for smaller wheel.

(6).Non-toxic,and can almost resist all pharmaceutical products.(7).Fire Proof.

(8).Air permeability of the conveyor belt can reduce the heat-consuming,

and improve the drying efficiency.

Applications:

Used in any industry which need conveyor belts in heat air flow or heat

processing.

(1).Textile and dyeing: drying for textile printing, dyeing, shrinking,

on-woven fabric, and in industry oven.

(2).The loose-dryer, offset, UV curing machine, paper oil drying, UV

drying, plastic printing drying.

(3).High-frequency wave drying, microwave drying, food refrigeration and defrost, baking, packaging heat shrinking.