- Overview

- Product Description

- Product Parameters

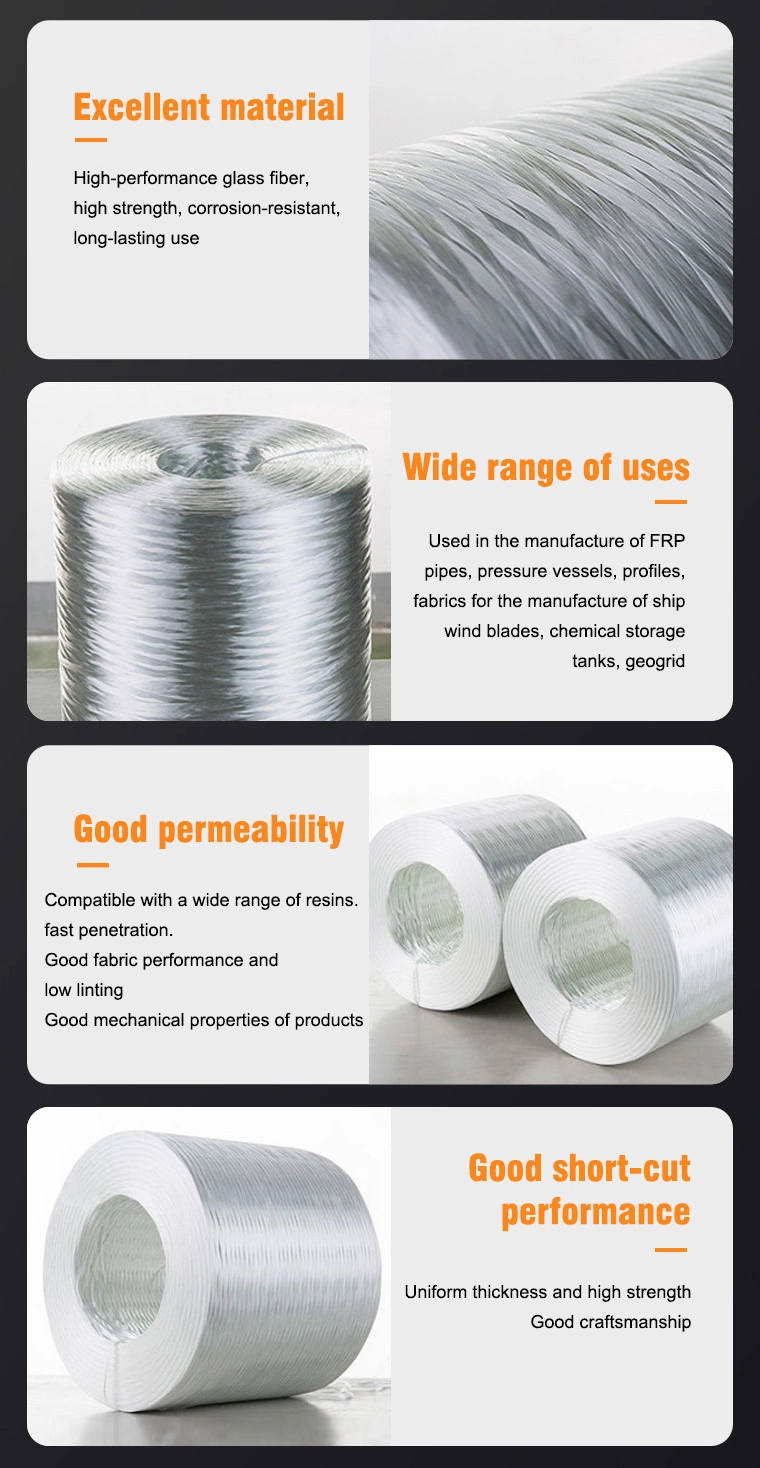

- Product Feature

- Application

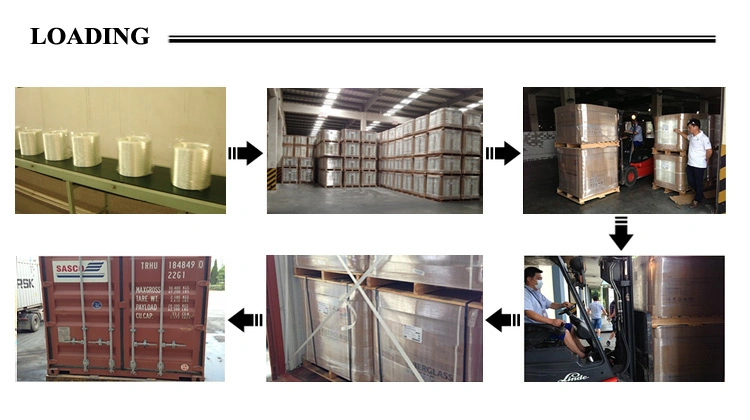

- Packaging & Shipping

- Company Profile

Basic Info.

Packaging & Delivery

Product Description

Different E-glass direct roving applies in different production processes and are compatible with various resins, including polyester, vinyl ester, epoxy and polyurethane. It covers Pultrusion,Filament Winding,Weaving,LFT and CFRT.

Direct Roving for weaving is compatible with unsaturated polyester, vinyl ester and epoxy resins.Its excellent weaving property makes it suited for fiberglass product, such as roving cloth, combination mats, stitched mat,multi-axial fabric,geotextiles,molded grating.The end-use products are widely used in building & construction, wind power and yacht applications.

| Item | Linear Density | Resin Compatibility | Features | End Use |

| BHW-01D | 800-4800 | Asphalt | High strand strength, Low fuzz | Suitable in manufacture of geotextiles, used to reinforce high-speed road |

| BHW-02D | 2000 | EP | Fast wet out, Excellent mechanical property of the composite product, High modulus | Suitable in manufacture of UD or multiaxial fabric, used as reinforcement of large wind energy blade by vacuum infusion process |

| BHW-03D | 300-2400 | EP,Polyester | Excellent mechanical properties of the composite product | Suitable in manufacture of UD or multiaxial fabric, used as reinforcement of large wind energy blade by prepreg process |

| BHW-04D | 1200,2400 | EP | Excellent weaving property, Excellent mechanical properties of the composite product, High modulus | Suitable in manufacture of UD or multiaxial fabric used as reinforcement of large wind energy blade by vacuum infusion process |

| BHW-05D | 200-9600 | UP | Low fuzz,Excellent weaving property;Excellent mechanical property of the composite products | Suitable for manufacture of UD or multiaxial fabric used as reinforcement of large polyester wind energy blade |

| BHW-06D | 100-300 | UP,VE,UP | Excellent weaving property, Excellent mechanical properties of the composite product | Suitable in manufacture of light weight roving cloth and multiaxial fabric |

| BHW-07D | 1200,2000, 2400 | EP,Polyester | Excellent weaving property; Excellent mechanical properties of the composite product | Suitable in manufacture of UD or multiaxial fabric, used as reinforcement of large wind energy blade by vacuum infusion process and prepreg process |

| BHW-08D | 200-9600 | UP,VE,UP | Excellent mechanical properties of the composite product | Suitable in manufacture of roving cloth used as reinforcement for pipes, yachts |

(1) Less hairiness, strong insulation, alkali resistance.

(2) Elongation within the limits of elasticity and high tensile strength, so it absorbs a lot of impact energy.

(3)Inorganic fiber, non-combustible, good chemical resistance.

(4) good permeability, no white silk.

(5)Not easy to burn, can be fused into glassy beads at high temperature.

(6) Good processability, can be made into strands, bundles, felts, fabrics and other different forms of products.

(7)Transparent and can transmit light.

(8)Fusion with many kinds of resin surface treatment agent.

Its excellent weaving property makes it suited for fiberglass product, such as roving cloth, combination mats, stitched mat,multi-axial fabric, geotextiles, molded grating.

The end-use products are widely used in building & construction, wind power and yacht applications.

Storage

Unless otherwise specified, fiberglass products should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15 ºC~35 ºC and 35%~65% respectively. To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high. When the pallets are stacked in 2 or 3 layers, care should be taken to correctly and smoothly move the top pallet.

The product should be transferred to the workshop 24 hours before use to undergo conditioning.

Packaging

The product can be packed on pallet or in small cardboard boxes.

| Package height mm(in) | 260(10) | 260(10) |

| Package inside diameter mm(in) | 160(6.3) | 160(6.3) |

| Package outside diameter mm(in) | 270(10.6) | 310(12.2) |

| Package weight kg (lb) | 15.6(34.4) | 22(48.5) |

| Number of layers | 3 | 4 | 3 | 4 |

| Number of doffs per layer | 16 | 12 | ||

| Number of doffs per pallet | 48 | 64 | 36 | 48 |

| Net weight per pallet kg (lb) | 750(1653.4) | 1000(2204.6) | 792(1764) | 1056(2328) |

| Pallet length mm (in) | 1120(44) | 1270(50) | ||

| Pallet width mm (in) | 1120(44) | 960(37.8) | ||

| Pallet height mm (in) | 940(37) | 1180(45) | 940(37) | 1180(46.5) |