Basic Info.

Model NO.

ud tapes

Ud Tape Fiber Types

Glass Fiber, Aramid Fiber, Carbon Fiber

Ud Tape Resin Types

Polypropylene(PP), Polyethylene(PE), Nylon(PA)

Tape Width

0-650mm, for Details, Please Contact Sales

Ud Tape Area Weight

250-650GSM

Processing Service

Bending, Decoiling, Moulding, Welding, Punching

Color

Natural, Black, Green, Grey, Customized

Advantage

Strong Strength, Lightweight, Recyclable

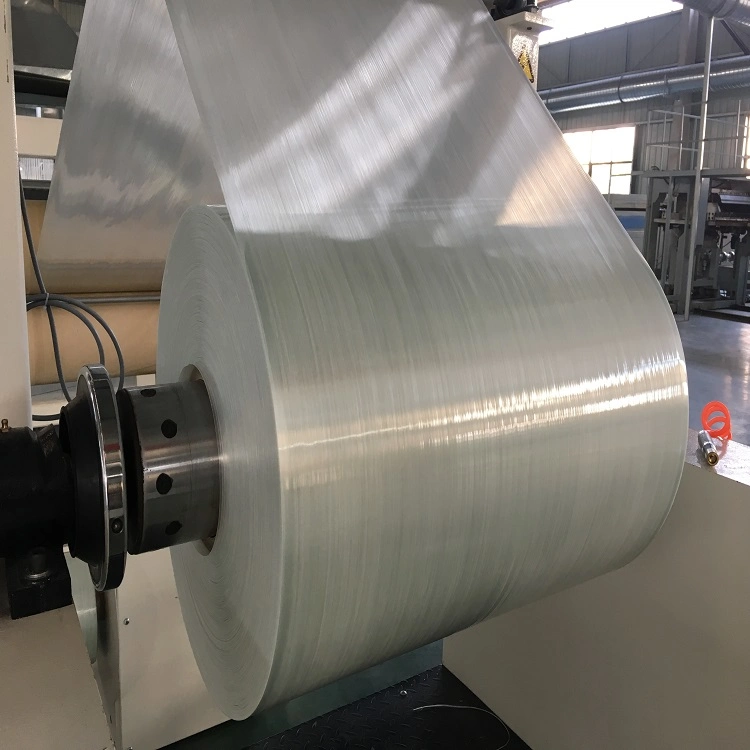

Max Length/Roll

3000m

Fiber

Glass Fiber, Carbon Fiber

Additive

Carbon Black, Anti-Aging, Antioxidant, Color Master

Application

Vehicle Parts, Sport Equipment, Sandwich Panels, Rtp

Technique

Melt Impregnation

Resin

PP, PE, PA6, PA1012, PETG, etc

Transport Package

Ud Tapes Packed as Per Request, Pallet, Plywood

Specification

as per request25mmX1000m,630mmX3000m, 1300mmX3000m

Origin

Qingdao, China

HS Code

3921902000

Production Capacity

900 Tons/Month

Product Description

High-performance Ud Tape for Oil and Gas Pipe Winding CFRTP unidirectional Tape Continuous Fiber Reinforced Fiberglass Thermoplastic Composites Tapes

Continuous glass fiber (GF) reinforced thermoplastic tape with unidirectional (UD) fiber orientation and a Polypropylene (PP) matrix in natural or black color.

Specification for Continuous glass fiber (GF) reinforced thermoplastic tape

| Fiber Types | glass fiber, aramid fiber, carbon fiber |

| Resin Types | Polypropylene (PP), Polyethylene (PE), Nylon (PA) |

| Tape Thickness | 0.15-0.4MM |

| Tape Areal Weight | 250gsm-620gsm |

| Tape Width | 0-650mm |

| Color | natural and black, other colors can be customized |

| Glass Fiber content | 0%-70% by weight |

| Application | Thermoplastic reinforced composite pipe, automotive parts, safety protection, wrapping cylinder, etc |

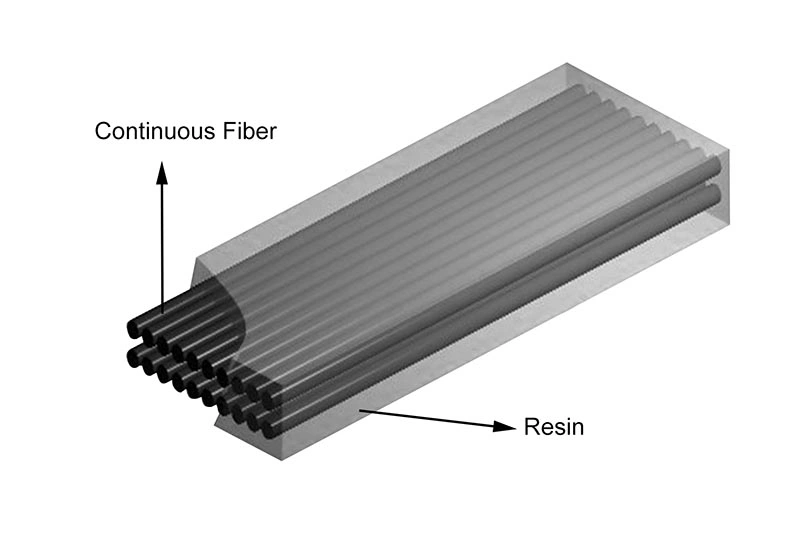

CFRT-UD Unidirectional belt

CFRT unidirectional tape is a single-layered, fiber-reinforced thermoplastic composite sheet in which the continuous fibers are unrolled and laid, and

impregnated with a thermoplastic resin. It is characterized by fibers arranged parallel to each other (0° direction) without interlacing. Product width:

300mm/600mm/1200mm, can be customized.

Main applications: automotive interior and exterior trims, thermoplastic winding pipes, sports leisure, home building materials, transportation logistics, and aerospace.

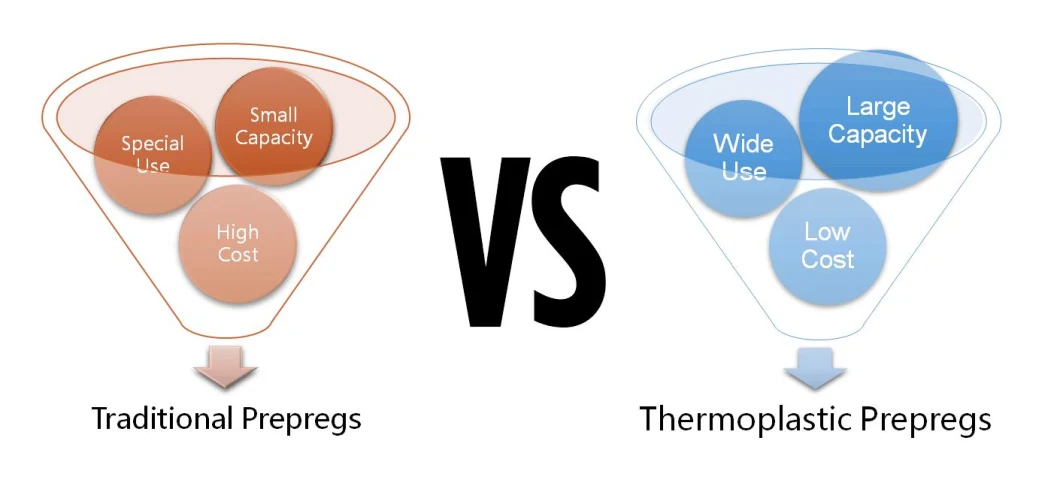

Features of Thermoplastic Unidirectional Fiberglass Prepreg Tapes

Short fiber reinforced thermoplastic material: fiber length <1MM.

Long fiber reinforced thermoplastic material: fiber length 1 ~ 25MM.

Continuous Fiber Reinforced Thermoplastics: Length consistent with final product dimensions

The data sheet of Thermoplastic Unidirectional Tape PP GF 70-250 µm

Physical Properties

Glass Fibre Content 70 %wt

Fibre Areal Weight 290 g/m²

Fibre volume content 46 %

Prepreg Areal Weight 416 g/m²

Nominal Thickness 0,25 mm

Available Widths 3 mm to 300 mm

Thermal Properties

Melting Temperature 165 °C

Processing Temperature 180 - 220 °C

Mechanical Properties

Tensile Strength 940 MPa

Tensile Modulus 35 GPa

Flexural Strength 610 MPa

Flexural Modulus 34 GPa

For other ud tapes data sheets, contact us freely.

**Typical values are the average laboratory data, only for reference, not as a product standard.

The performance of continuous fiber reinforced thermoplastic composites is very excellent. The longer the fiber length, the better the mechanical properties. Its specific strength can be more than 10 times that of ordinary steel. The higher the specific strength, the lighter the material used to achieve the corresponding strength. , so the continuous fiber-reinforced thermoplastic composite material can realize the real sense of replacing steel with plastic and lightweight applications.

Melt impregnation method is currently the most widely used and most industrialized method for manufacturing unidirectional belts. The process of the melt impregnation method is that the continuous fibers are fully impregnated with the molten thermoplastic resin through the process of yarn laying and yarn spreading, and through the impregnation mechanism.

Why us?

Good fiber dispersion:

The glass fiber is dispersed individually in the resin, which overcomes the problem of thermoplastic fiber dispersion.

Customized production:

using the melting process to meet different special performance requirements.

Mass production:

In mass production, the production cost is relatively low, and the quality is stable and reliable.