Basic Info.

Model NO.

ECR13-2000-181

Trademark

Moresu

Origin

China

Product Description

General Informations

Glass-fiber (sometimes also called Fibreglass) is an inorganic non-metallic material with excellent properties. Its advantages are good insulation, strong heat resistance, good corrosion resistance and high mechanical strength but less abrasive.

The diameter of its single filament is normally below 20 microns, and each bundle of fiber filaments is composed of hundreds or even thousands of single filaments.

The diameter of its single filament is normally below 20 microns, and each bundle of fiber filaments is composed of hundreds or even thousands of single filaments.

The glass fiber is often used as reinforcing material of composite material, electrical insulation and heat insulation materials.

Glass-fiber can be divided into continuous fiber (long fiber) and fixed length fiber (short fiber) according to its shape and length.

Glass-fiber can be divided into continuous fiber (long fiber) and fixed length fiber (short fiber) according to its shape and length.

The most common type of glass in glass-fibre used for plastic industry is

1) E-glass - alumino-borosilicate glass with less than 1% w/w alkali oxides, mainly used for glass-reinforced plastics

2) - E-CR-glass - Electrical/Chemical Resistance; alumino-lime silicate with less than 1% w/w alkali oxides, with high acid resistance.

For quick reference of glass used: A-glass ("A" for "alkali-lime"), E-glass ("E" because of initial electrical application), S-glass ("S" for "Strength"), R-glass ("R" for "reinforcement"), C-glass ("C" for "chemical resistance") and T-glass ("T" is for "thermal insulator" )

Uses for regular glass fiber include mats and fabrics for thermal insulation, electrical insulation, sound insulation, high-strength fabrics or heat- and corrosion-resistant fabrics. It is also used to reinforce various materials, such as tent poles, pole vault poles, arrows, bows and crossbows, translucent roofing panels, automobile bodies, hockey sticks, surfboards, boat hulls, and paper honeycomb. It has been used for medical purposes in casts. Glass fiber is extensively used for making FRP tanks and vessels.

Open-weave glass fiber grids are used to reinforce asphalt pavement. Non-woven glass fiber/polymer blend mats are used saturated with asphalt emulsion and overlaid with asphalt, producing a waterproof, crack-resistant membrane. Use of glass-fiber reinforced polymer rebar instead of steel rebar shows promise in areas where avoidance of steel corrosion is desired.

Open-weave glass fiber grids are used to reinforce asphalt pavement. Non-woven glass fiber/polymer blend mats are used saturated with asphalt emulsion and overlaid with asphalt, producing a waterproof, crack-resistant membrane. Use of glass-fiber reinforced polymer rebar instead of steel rebar shows promise in areas where avoidance of steel corrosion is desired.

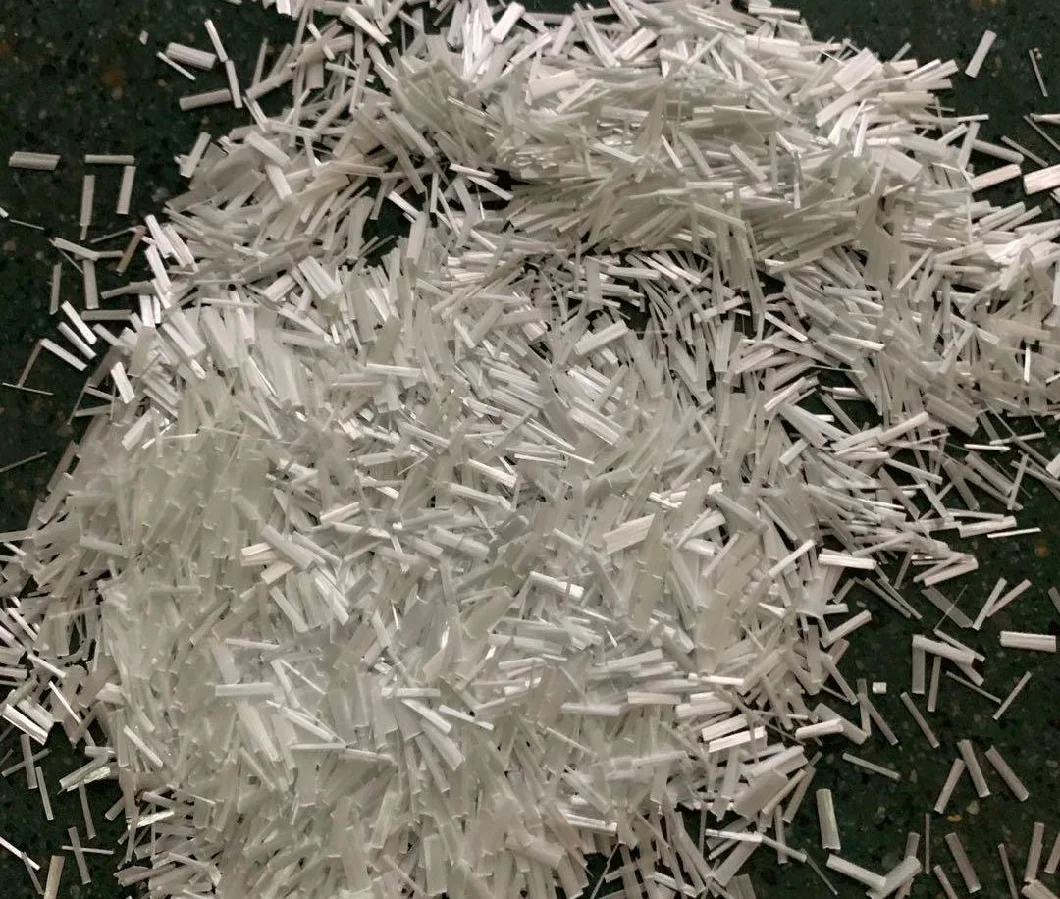

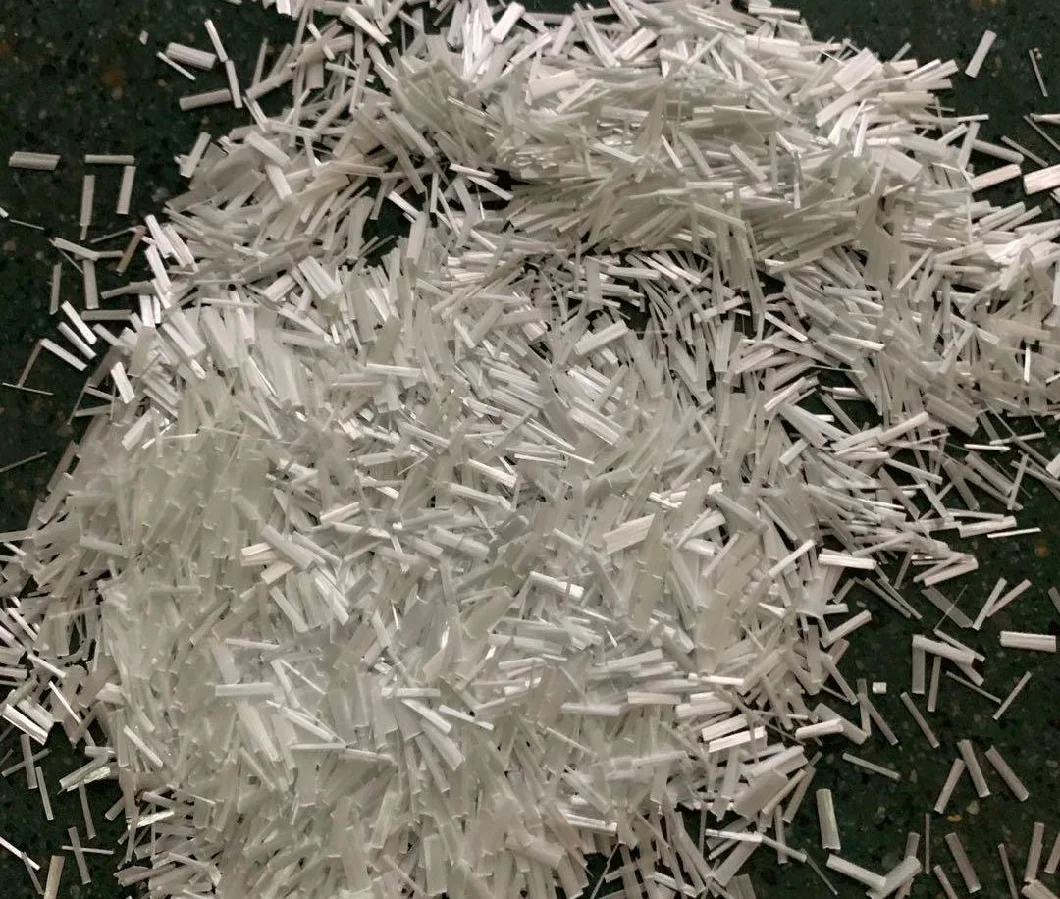

Moresu ECR13-2000-181

This 181 assembled roving is a long fiber for reinforced thermoplastic, coated with Si nH 2 n +2 base sizing agent, and compatible with a variety of resin.

It is a direct yarn that mainly used in extrusion process and is widely used in automobile parts, electronic and electrical, mechanical tools, chemical anti-corrosion, sports goods and etc.

It is a direct yarn that mainly used in extrusion process and is widely used in automobile parts, electronic and electrical, mechanical tools, chemical anti-corrosion, sports goods and etc.

The advantages of Moresu ECR13-2000-181:

The advantages of Moresu ECR13-2000-181:

- Good extrusion shearing property,

- easy dispersion of glass fiber,

- good smoothness of use,

- less burrs,

- stable linear density,

- even glass fiber content of products,

- excellent mechanical properties of composites,

- good combination with resins

Specification

Technical Data

Packing information

Pallet packaging, average weight of each yarn roll is 22kg

We have a full range of products with different glass type, fibre diameter and fibre length, please let us know your requirements and we can recommended the most suitable material for you.

Glass-fiber (sometimes also called Fibreglass) is an inorganic non-metallic material with excellent properties. Its advantages are good insulation, strong heat resistance, good corrosion resistance and high mechanical strength but less abrasive.

The diameter of its single filament is normally below 20 microns, and each bundle of fiber filaments is composed of hundreds or even thousands of single filaments.

The diameter of its single filament is normally below 20 microns, and each bundle of fiber filaments is composed of hundreds or even thousands of single filaments.The glass fiber is often used as reinforcing material of composite material, electrical insulation and heat insulation materials.

Glass-fiber can be divided into continuous fiber (long fiber) and fixed length fiber (short fiber) according to its shape and length.

Glass-fiber can be divided into continuous fiber (long fiber) and fixed length fiber (short fiber) according to its shape and length.The most common type of glass in glass-fibre used for plastic industry is

1) E-glass - alumino-borosilicate glass with less than 1% w/w alkali oxides, mainly used for glass-reinforced plastics

2) - E-CR-glass - Electrical/Chemical Resistance; alumino-lime silicate with less than 1% w/w alkali oxides, with high acid resistance.

For quick reference of glass used: A-glass ("A" for "alkali-lime"), E-glass ("E" because of initial electrical application), S-glass ("S" for "Strength"), R-glass ("R" for "reinforcement"), C-glass ("C" for "chemical resistance") and T-glass ("T" is for "thermal insulator" )

Uses for regular glass fiber include mats and fabrics for thermal insulation, electrical insulation, sound insulation, high-strength fabrics or heat- and corrosion-resistant fabrics. It is also used to reinforce various materials, such as tent poles, pole vault poles, arrows, bows and crossbows, translucent roofing panels, automobile bodies, hockey sticks, surfboards, boat hulls, and paper honeycomb. It has been used for medical purposes in casts. Glass fiber is extensively used for making FRP tanks and vessels.

Open-weave glass fiber grids are used to reinforce asphalt pavement. Non-woven glass fiber/polymer blend mats are used saturated with asphalt emulsion and overlaid with asphalt, producing a waterproof, crack-resistant membrane. Use of glass-fiber reinforced polymer rebar instead of steel rebar shows promise in areas where avoidance of steel corrosion is desired.

Open-weave glass fiber grids are used to reinforce asphalt pavement. Non-woven glass fiber/polymer blend mats are used saturated with asphalt emulsion and overlaid with asphalt, producing a waterproof, crack-resistant membrane. Use of glass-fiber reinforced polymer rebar instead of steel rebar shows promise in areas where avoidance of steel corrosion is desired. Moresu ECR13-2000-181

This 181 assembled roving is a long fiber for reinforced thermoplastic, coated with Si nH 2 n +2 base sizing agent, and compatible with a variety of resin.

It is a direct yarn that mainly used in extrusion process and is widely used in automobile parts, electronic and electrical, mechanical tools, chemical anti-corrosion, sports goods and etc.

It is a direct yarn that mainly used in extrusion process and is widely used in automobile parts, electronic and electrical, mechanical tools, chemical anti-corrosion, sports goods and etc.  The advantages of Moresu ECR13-2000-181:

The advantages of Moresu ECR13-2000-181:- Good extrusion shearing property,

- easy dispersion of glass fiber,

- good smoothness of use,

- less burrs,

- stable linear density,

- even glass fiber content of products,

- excellent mechanical properties of composites,

- good combination with resins

Specification

| Model no. | ECR13-2000-181 |

| Glass type | ECR |

| Fibre diameter (μm) | 13 |

| Filaments per bundle | 2000 |

| Sizing agent | 181 |

Technical Data

| Deviation of Filaments per bundle (%) | Moisture content (%) | Flammable content (%) | Tensile strength (N/tex) |

| ISO1819 | ISO3344 | ISO1817 | ISO3375 |

| ±5 | ≤0.10 | 0.30±0.10 | ≥0.25 |

Packing information

Pallet packaging, average weight of each yarn roll is 22kg

| Yarn roll height (mm) | 260 | Layer for each pallet | 3 | 4 | |

| Yarn roll internal diameter (mm) | 160 | no. of yarn roll per layer | 12 | ||

| Yarn roll external diameter (mm) | 310 | no. of yarn roll per pallet | 36 | 48 | |

| Yarn roll weight (kg) | 22 | Total weight per pallet (kg) | 792 | 1,056 | |

We have a full range of products with different glass type, fibre diameter and fibre length, please let us know your requirements and we can recommended the most suitable material for you.