- Overview

- Product Description

- Application

- Technical Data

- Packaging

- <span cke-mic-navigation-content="" style="border-radius:3px;padding:0 10px;display:inline-block;line-height:36px;text-align:left;"><span style="font-size:16px;"><span cke-mic-navigation-content="" style="border-radius:3px;padding:0 10px;display:inline-block;line-height:36px;text-align:left;"><span cke-mic-navigation-content="" style="border-radius:3px;padding:0 10px;display:inline-block;line-height:36px;text-align:left;"><span cke-mic-navigation-content="" style="border-radius:3px;padding:0 10px;display:inline-block;line-height:36px;text-align:left;"><span style="font-size:16px;"><span cke-mic-navigation-content="" style="border-radius:3px;padding:0 10px;display:inline-block;line-height:36px;text-align:left;"><span cke-mic-navigation-content="" style="border-radius:3px;padding:0 10px;display:inline-block;line-height:36px;text-align:left;"><span cke-mic-navigation-content="" style="border-radius:3px;padding:0 10px;display:inline-block;line-height:36px;">Company Profile</span></span></span></span></span></span></span></span></span>

- <span cke-mic-navigation-content="" style="border-radius:3px;padding:0 10px;display:inline-block;line-height:36px;text-align:left;"><span style="font-size:16px;"><span cke-mic-navigation-content="" style="border-radius:3px;padding:0 10px;display:inline-block;line-height:36px;text-align:left;"><span cke-mic-navigation-content="" style="border-radius:3px;padding:0 10px;display:inline-block;line-height:36px;text-align:left;"><span cke-mic-navigation-content="" style="border-radius:3px;padding:0 10px;display:inline-block;line-height:36px;text-align:left;"><span style="font-size:16px;"><span cke-mic-navigation-content="" style="border-radius:3px;padding:0 10px;display:inline-block;line-height:36px;text-align:left;"><span cke-mic-navigation-content="" style="border-radius:3px;padding:0 10px;display:inline-block;line-height:36px;text-align:left;"><span cke-mic-navigation-content="" style="border-radius:3px;padding:0 10px;display:inline-block;line-height:36px;text-align:left;">FAQ</span></span></span></span></span></span></span></span></span>

Basic Info.

Packaging & Delivery

Product Description

Fiberglass Surfacing Tissue is characterized by uniform fiber dispersion, smooth surface, and fast resin impregnation. It is mainly used in the surface layer of FRP products of which the capability is ameliorated. It is capable of significantly improving the strength of the FRP surface layer, strong impaction resistance, excellent uniformity of surface, good covering up the texture of under layers, and good corrosion resistance. According to different customers´ Requirements, this company developed the S-BM mat. We also classify control for the different specifications according to the different forming processes. These products can satisfy the different process requirements of hand lay-up, cement winding, and pull trussing, serving customers and guaranteeing good quality for the later products.

1. Hand lay-up type FRP surface tissue

Hand lay-up type FRP surface mat is mainly applied in producing hand lay-up FRP products. It has the advantages of good pattern fitness and quick resin permeating. It is characterized as covering up the texture of layers, making the surface smooth, and improving the service life.2. Wrap type FRP surface tissue

The wrap-type FRP surface mat is mainly suitable for wrapping FRP pipes and vessels. It has absorbed a great deal of resin and the defendable layer has been formed at the FRP product surface. It is capable of significantly improving the performance of the surface layer to realize a longer lifetime and resistance against corrosion, leakage, and compression.

3. S-BM (P) (Pull trussing type surface tissue)

The pull trussing type surface mat could improve the strength of the profiled material surface layer. It could ameliorate the capability and avoid cracking of the product.

| F-BM Series(FRP Surface tissue(W)) | ||||||

| Items | Type | |||||

| Unit | F-BM(W)20 | F-BM(W)30 | F-BM(W)40 | F-BM(W)50 | F-BM(W)60 | |

| Monofilament Diameter | μ m | 9-12 | ||||

| Area weight | g/m 2 | 20 | 30 | 40 | 50 | 60 |

| Binder Content | % | 6-9 | ||||

| Penetrating time(two layers) | S | 8 | 10 | 15 | 20 | 25 |

| Tensile Strength MD | N/50mm | 35 | 40 | 50 | 60 | 70 |

| Moisture content | % | <0.2<> | ||||

| Roll Width | mm | The roll width can be produced according to the customers' requirements. | ||||

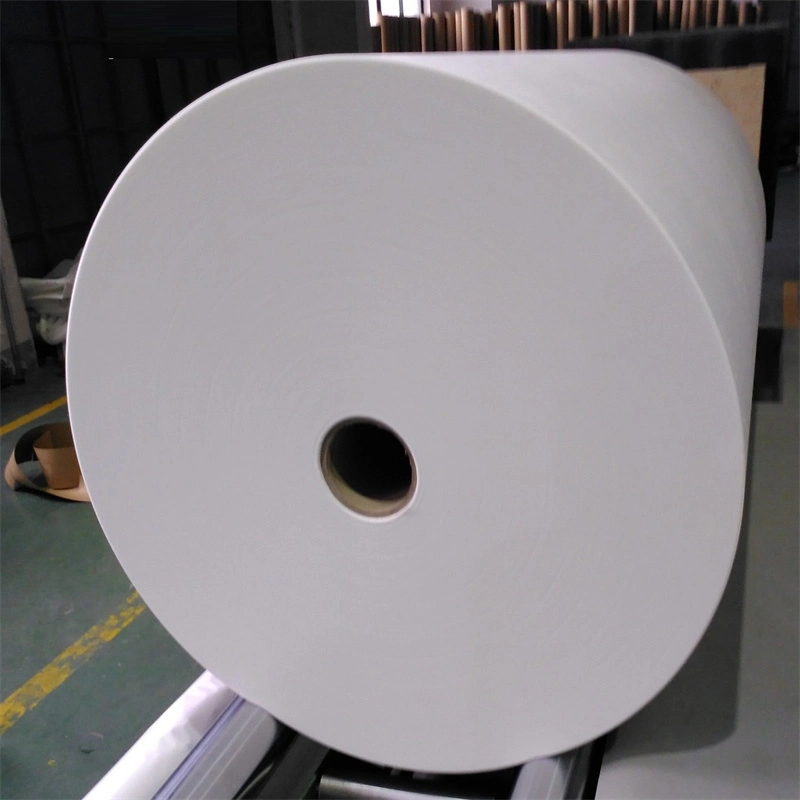

Each Surface Tissue is wound onto a paper tube with an inside diameter of 76mm and the mat roll diameter of 330mm. The mat roll is wrapped up with plastic film, and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be vertically or horizontally placed. For transportation, the rolls can be loaded into a container directly or on pallets.